Coil decoiler:

1. Loading capacity: 1.5T

2. Uncoiling width: 300mm

3. Inner diameter: 450-550mm

4. Has power, it can work automatically

5. Automatically adjust the decoiler to fit into the coil accorind to the coil diameter.

Feeding Device

1.The surface of the material is protected from scratches by 4-6 stainless steel rollers, preventing the raw material from jumping up and down during feeding.

2.With hand wheels easy adjust for feeding different thickness raw material.

3. The platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet.

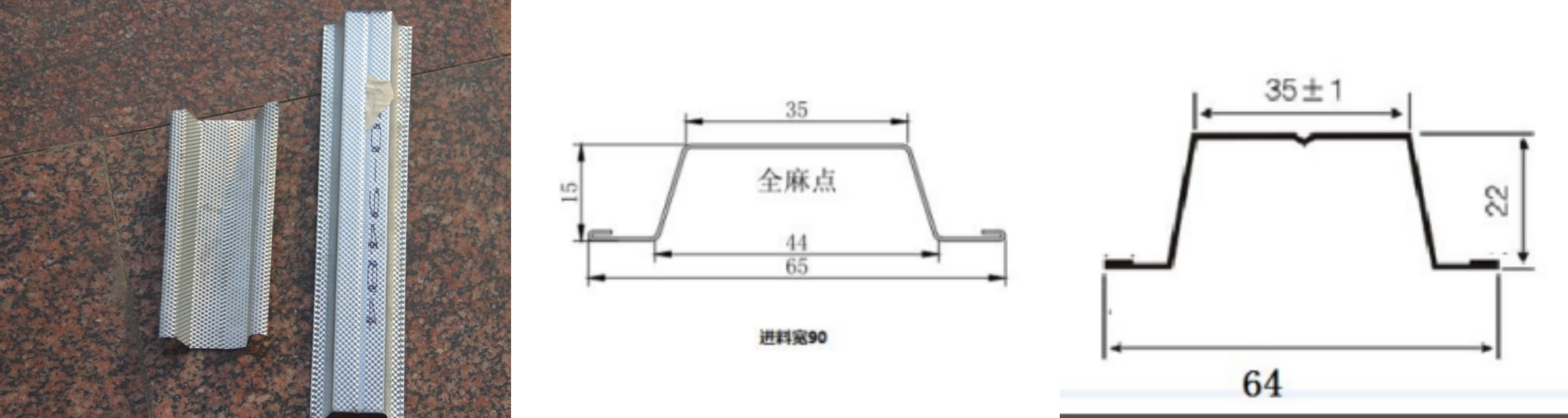

Roll forming machine:

1. Voltage: 380V/50HZ 3Phase (as customer’s request)

2. Raw material: Galvanized steel

3.Frame body:Memorial arch frame

4. Frame thickness: 25mm

5. Drive mode: gear

6. Material of rollers: GCr12MoV

7. Material of shafts: 45# steel with tempering

8. Diameter of shafts: φ40-60mm

9. Roller station: 12 stations(according to profile drawing)

Shearing device:

Together with punching words, cutting will be done together.

1. Material of blades: Gcr12 quenched

2. Cutting type: Hydraulic cutting

3. Automatic hydraulic cutting after forming, no distorting or wasting.

Hydraulic Station:

1. Hydraulic motor Power: 5.5kw

2. Hydraulic oil: 46#

Control System:

Delta PLC control

Delta touch screen

Program language: English/Chinese(or as required)

Packing and shipping: