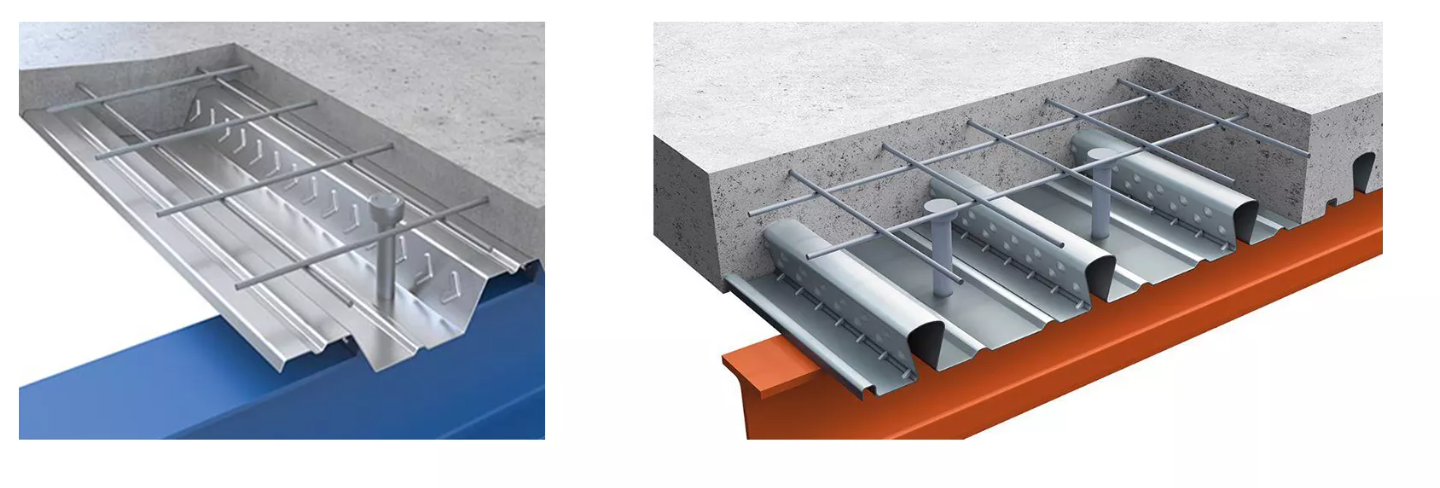

Profile of floor deck:

Decoiler:

Function:To support the coil for production

Types:Manual and automatic for option

Capacity:Normal 5 tons,other weight also can customized

Roll former product parmeters:

| Floor Deck Roll Forming Machine | ||

Machinable Material | A) Galvanized Coil | Thickness(MM): 0.7-1.2 even up to 1.5 as per customer |

| B) PPGI, PPGL | ||

| Yield Strength | 250 – 350 Mpa | |

| Tensil Stress | 350 Mpa-500 Mpa | |

| Coil Width | 914mm, 1000mm, 1200mm, 1220mm, 1250mm etc | |

| Nominal Forming Speed(M/Min) | 10-15 | * Or According To Your Requirement |

| Forming Station | About 24-32 | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Chain Drive | * Gearbox Drive (Optional) |

| Machine Structure | Steel Plates Welded | * Cast Iron Stands (Optional) |

| Rollers’ Material | GCr 15 | * Cr12Mov (Optional) |

| Cutting System | Hydraulic Post Cut | |

| Frequency Changer Brand | Yaskawa | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Control system:

Our machine adopt famous brand in the control system,such as Siemens PLC and touch screen,Schneider low voltage apparatus and omron encoder,these brand electric parts have after-sale service in the whole world which is more convenient for customer

Hydraulic system:

Our hydraulic system is equipped with the fan cooling system,it can cool down the oil during long time working or at hot weather

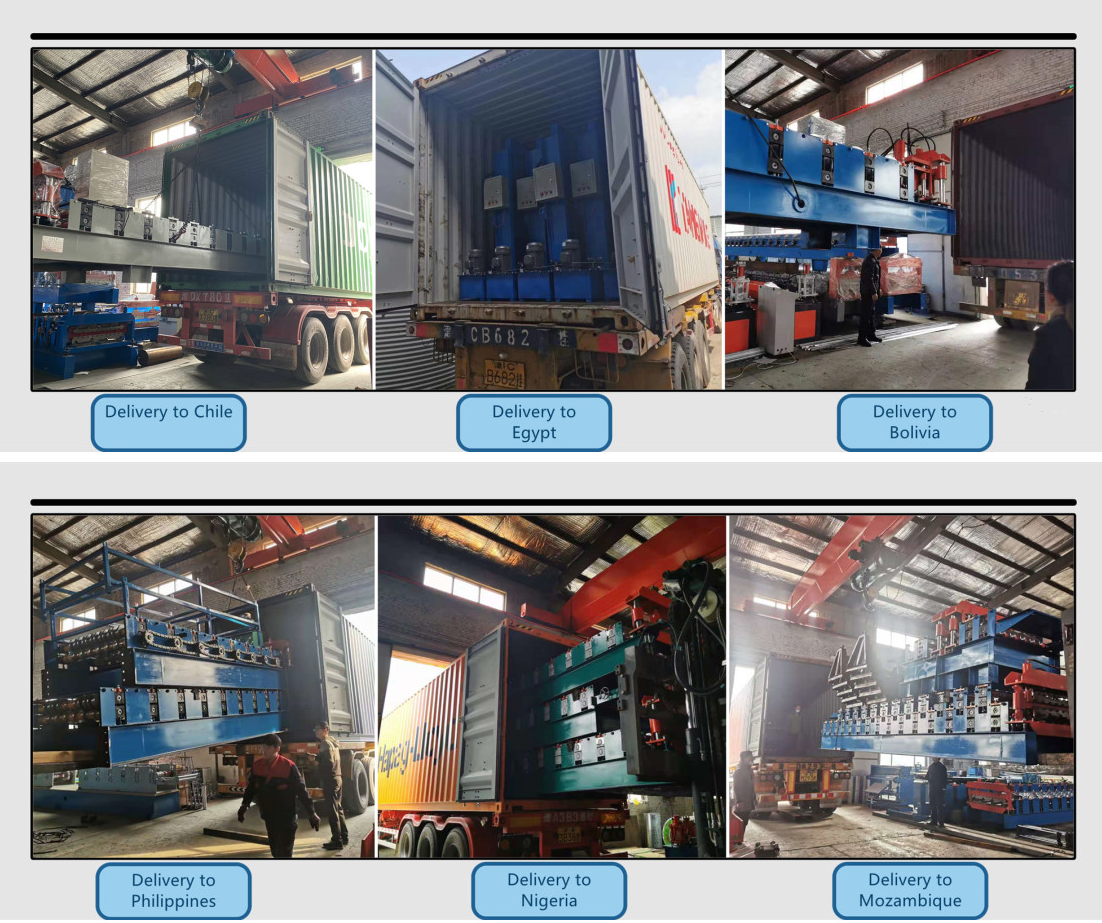

Packing and shipping:

Nude, with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

TG RFM has been in this industry for more than two decades, so we have a lot of experience in the machines. We support customization as our customer’s request, welcome to contact us!