Production Profile:

Production Line:

Production Parameters:

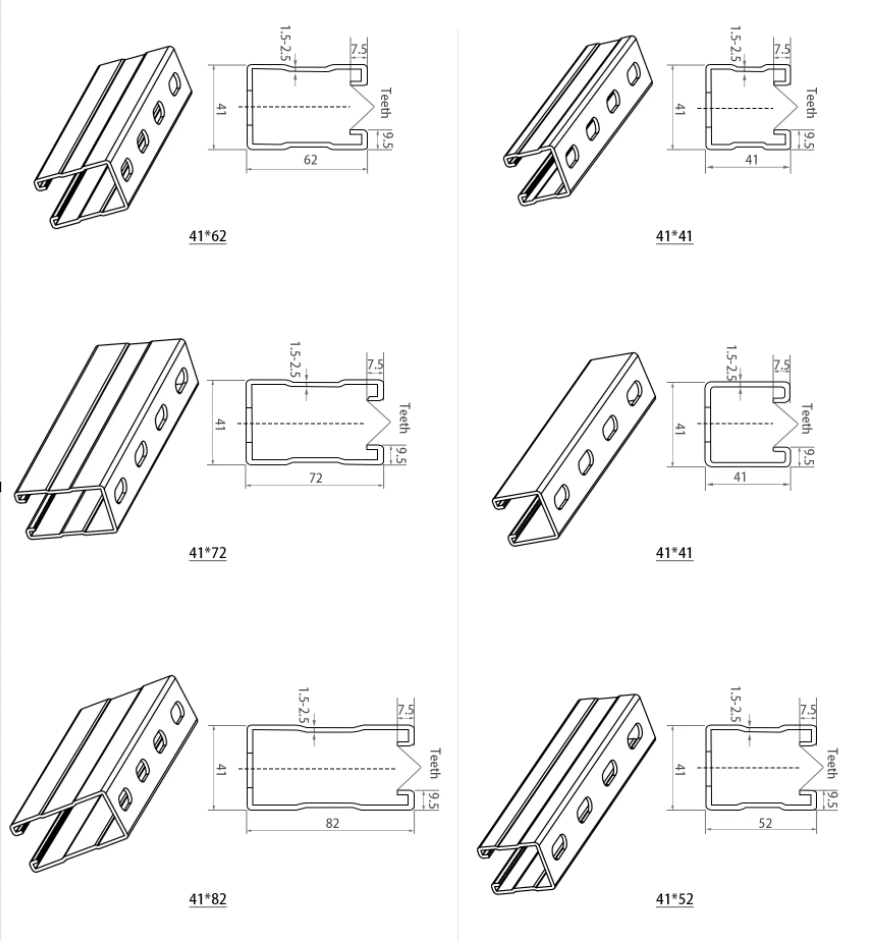

Strut Channel Roll Forming Machine (Updated Version) | ||

Machinable Material | A) Hot-rolled And Cold Rolled Steel | Thickness(MM): 1.5-2.0, 2.0-2.5, up to 3mm |

B) Hot-dip Galvanized Sheet | ||

C) Pre-Galvanized Steel | ||

D) Mill (Plain/Black) Steel | ||

Yield strength | 250 – 550 Mpa | |

Tensil stress | G250 Mpa-G350 Mpa | |

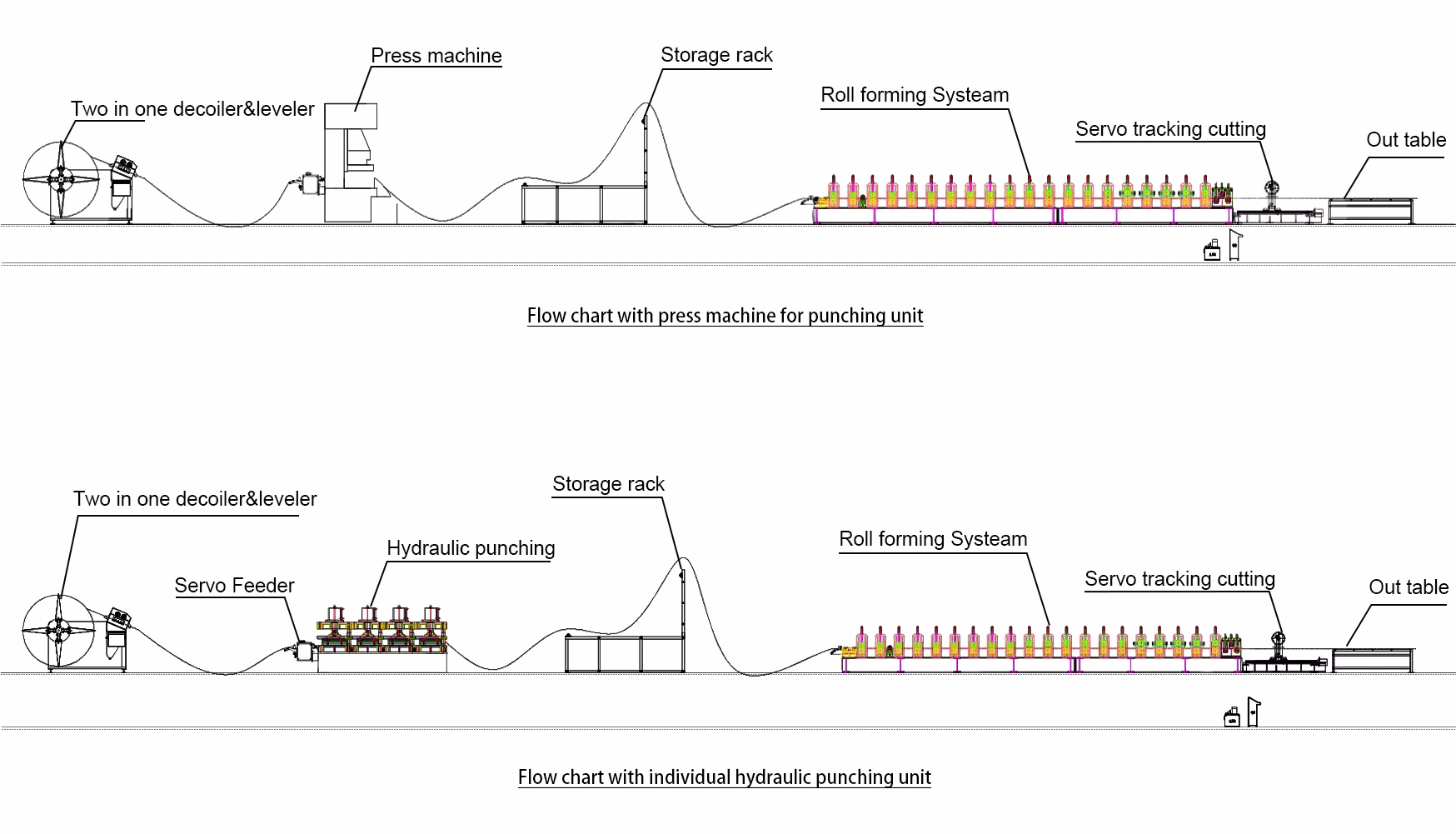

Decoiler | Hydraulic Decoiler | * 2 in 1 Decoiler With Leveler And Servo Feeder (Optional) |

Punching System : | Hydraulic Punching Station (Individual) | * Punching Press (Optional) |

Forming Station | 20-22 Or 24-28 For Anti-seismic Strut | * According To Your Profile Drawings |

Driving System | Gearbox Drive | |

Machine Structure | Forged Iron station | |

Line Forming Speed | 15-20 (M/MIN) | * According To Final Configuration |

Rollers’ Material | GCr15 | * Cr12 (Optional) |

Cutting System | Post-cutting, Machine Stop To Cut | * Tracking Cutter (Optional) |

Frequency Changer Brand | Delta | |

PLC Brand | Delta | |

Power Supply | 380V 50Hz 3ph | * Or According To Your Requirement |

Machine Color | Industrial Blue | * Or According To Your Requirement |

Production Details:

Application: