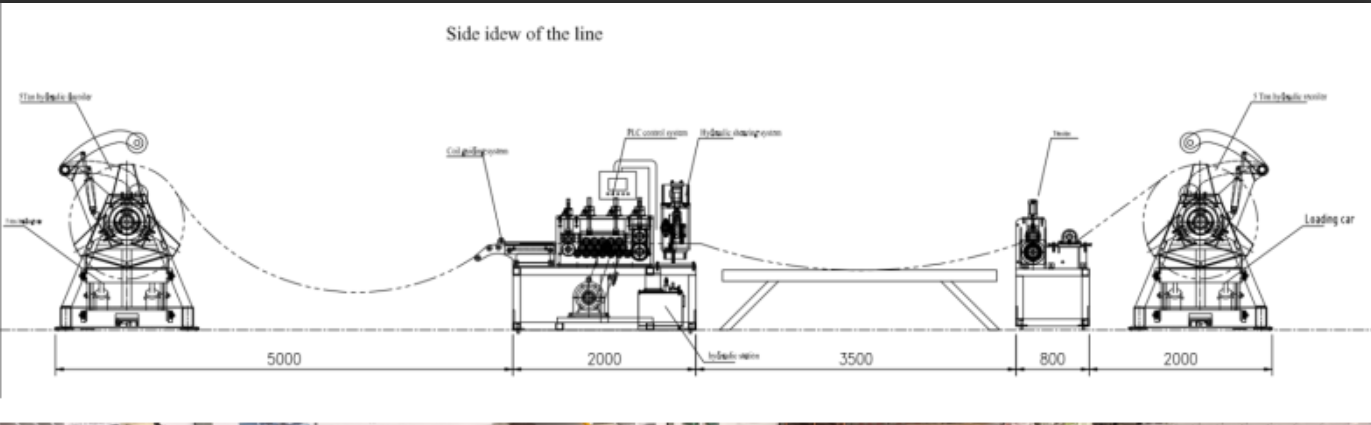

Production Line:

| Part 2: Leveling, slitting and cut to length | |

| Feeding device | Adjustable |

| Leveling roller number | 13 rollers, 5up 6down |

| Leveling roller diameter | 50mm |

| Roller material | High grade 45# steel |

| Shaft diameter | 80 mm |

| Work speed | 0-15 m/min |

| Machine basic frame | Steel plate welded |

| Power system | Motor drive, driven by the speed reducer and then give power to gear. |

| Driving power | 7.5 kw |

| Material thickness adjusting | By lifter, convenient to adjust for different thickness of material |

Details of Leveling,slitting and cut to length:

| Feeding device | Adjustable |

| Leveling roller number | 13 rollers, 5up 6down |

| Leveling roller diameter | 50mm |

| Roller material | High grade 45# steel |

| Shaft diameter | 80 mm |

| Work speed | 0-15 m/min |

| Machine basic frame | Steel plate welded |

| Power system | Motor drive, driven by the speed reducer and then give power to gear. |

| Driving power | 7.5 kw |

| Material thickness adjusting | By lifter, convenient to adjust for different thickness of material |

![]()

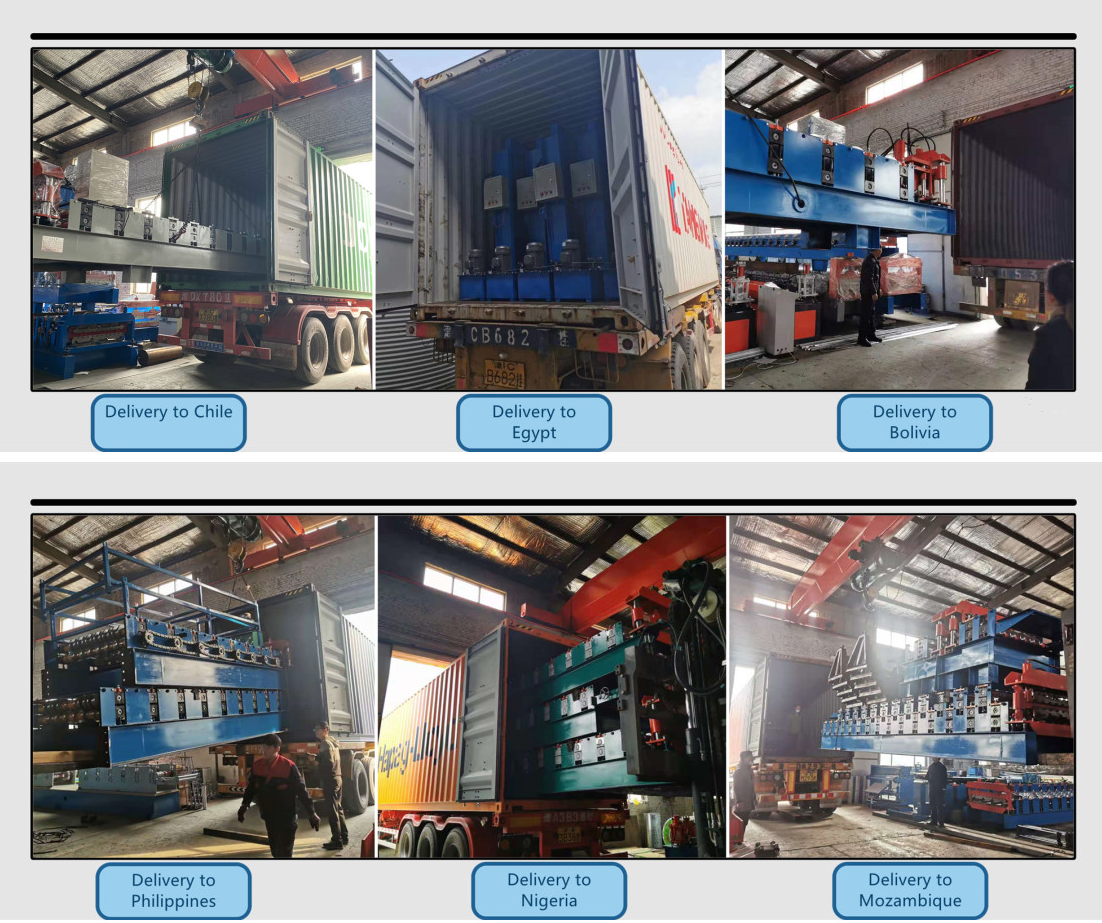

Packing and shipping:

Nude, with waterproof cloth and stow-wood. Imported computer control system packed with waterproof cloth and card board.

TG RFM has been in this industry for more than two decades, so we have a lot of experience in the machines. We support customization as our customer’s request, welcome to contact us!