Product Details:

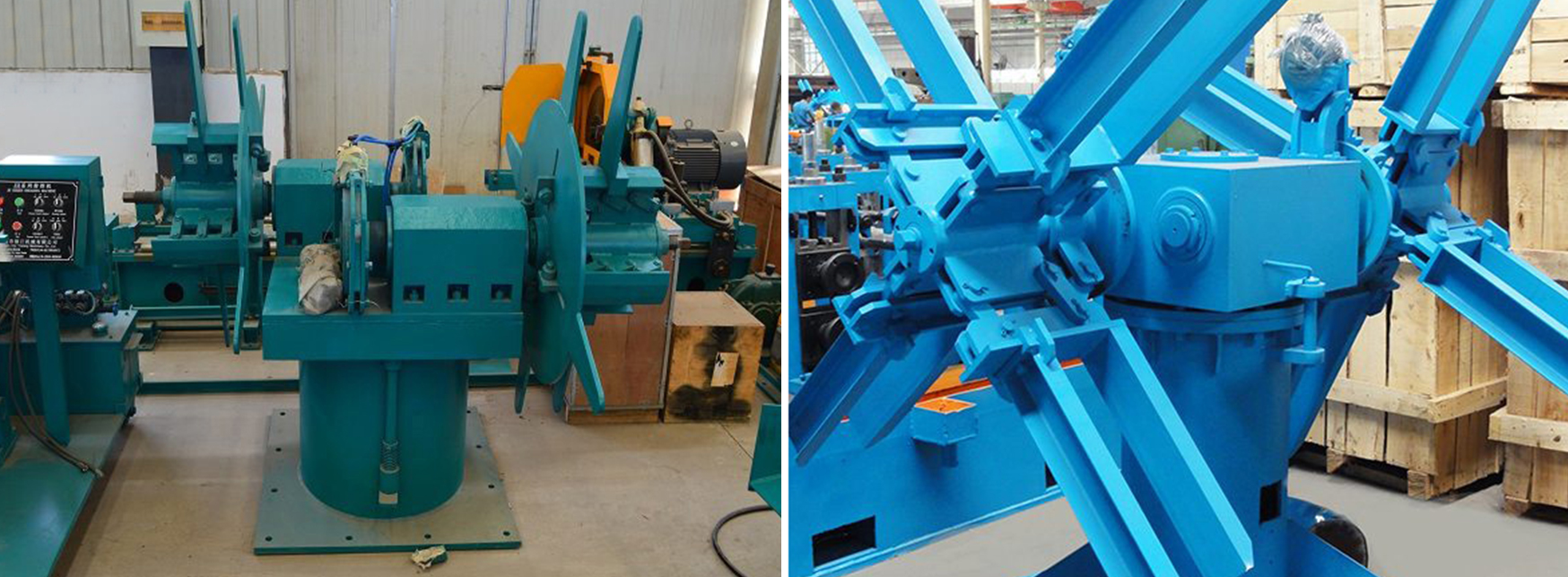

Double Cone Decoiler is used to support the coil and provide raw materials for the production line. The reel is cantilever type, pneumatic expansion and contraction; in order to maintain the tension of the strip and prevent loose coiling, the reel adopts pneumatic brake.

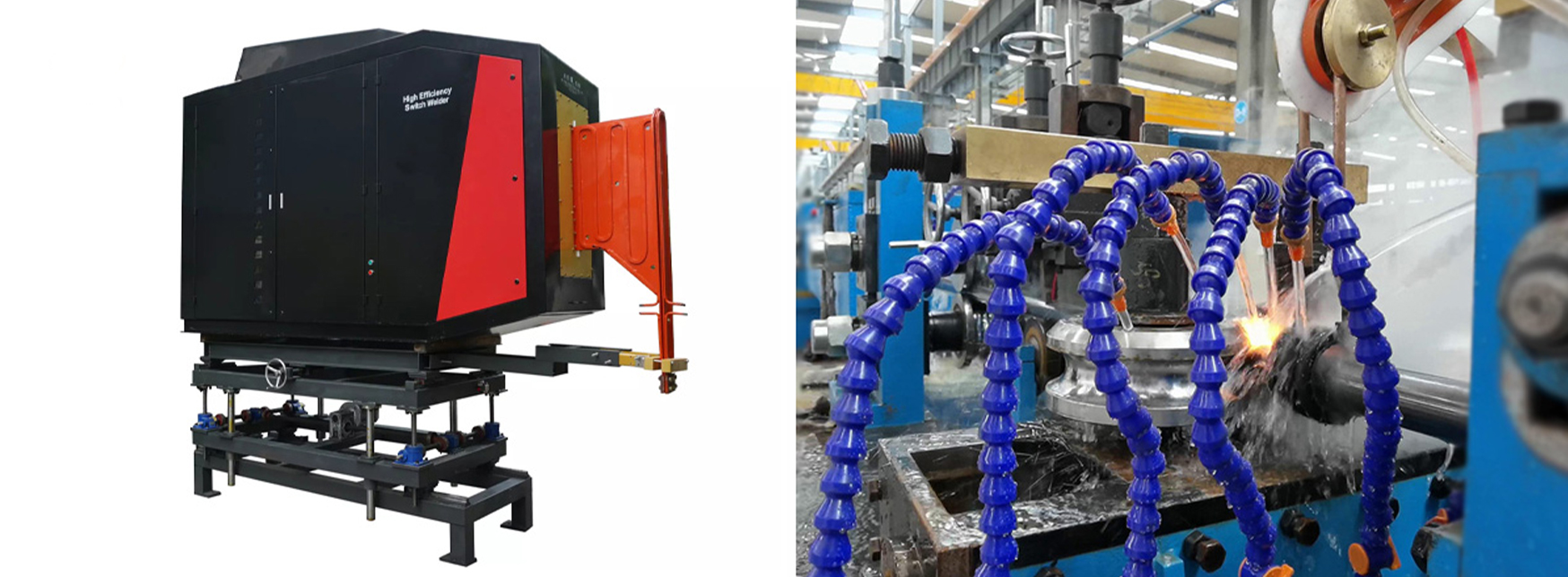

Shearing and Automatic Welding Machine is connect the strips after cutting the preceding coil tail end and the succeeding coil top end and being welded together by CO2 gas shielding welding to keep the Pipe Welding Line running continuously. Type: Automatic welding by TIG welder.

The vertical accumulator is used to store steel strips to ensure continuous operation of the host when welding two coils. Occupy small space.

The horizontal accumulator is used to store steel strips to ensure continuous operation of the host when welding two coils.

Advantage: The feeding is more stable, without bending, while reducing the resistance of the feeding, it will not cause damage to the galvanized layer surface, and the noise is relatively lower.

High frequency welding equipment designed for both single and dual coil induction application and HF contact welding processes, these welders offer optimal flexibility for your production. Power range: from 150 to 500kW, Low industrial water consumption.

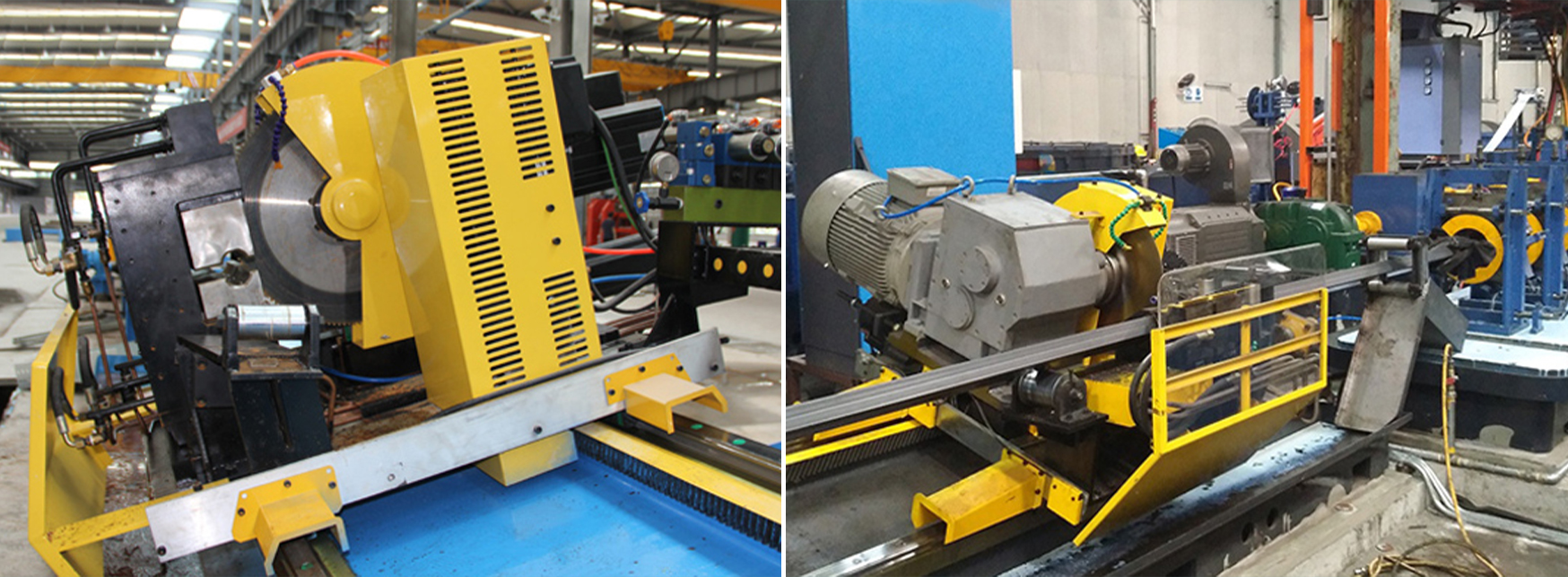

Commonly known as chopping saw, computer flying saw, also called friction saw. High-speed cutting is accompanied by high temperature and sparks, and the cutting end surface is purple.

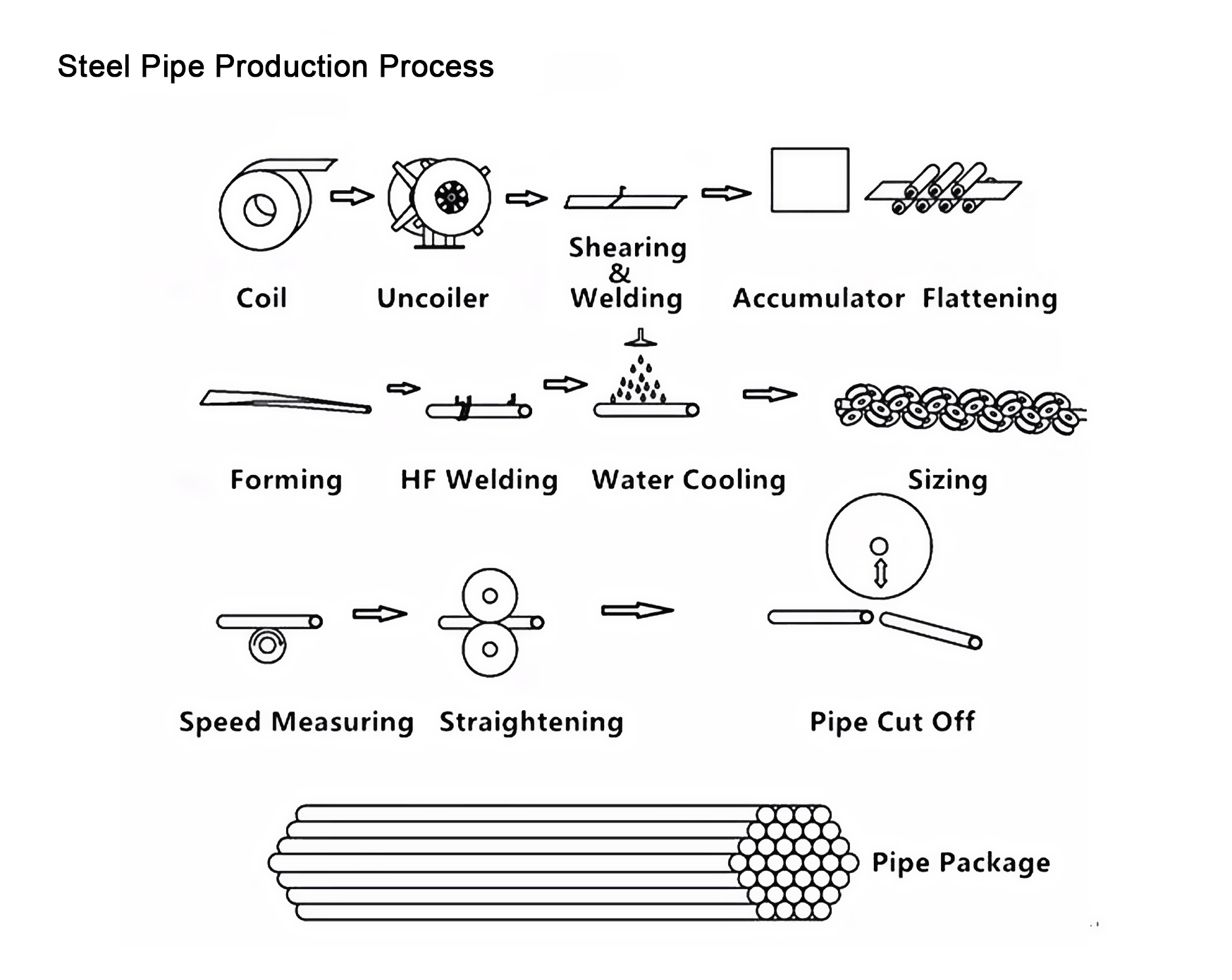

Production Line

Scrolling Up → Uncoiling → Shear And Welding → Spiral Accumulator→ Forming → H.F. Induction Welding → External Burr Removing → Cooling → Sizing → Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse

Product Advantages

High yielding, the machine works stably at a high speed, which improves the yielding of products.

Low wastage, low unit wastage and low production cost.

High accuracy, diameter error is only 0.5/100 of the pipe OD.

High production efficiency, line speed can be up to 120m/min.

Product Paramenters

| Item | Parameter | Thickness |

|---|---|---|

| Round Pipe | 16mm-50.8mm | 0.6mm-3.0mm |

| Square & Rectangle Tube | 20mm*20mm-50mm*50mm 10mm*20mm-25mm*50mm | 0.8mm-2.0mm |

| Length | 6m-12m Length Tolerance: ±3mm | |

| Production Speed | 20-120 m/min | |

| Production Capacity | 15,000 ton/year | |

| Carbon Steel Coil | Q235B(ASTM GR·D,σs 230) | |

| Width | 65mm-190mm | 0.8mm-3.0mm |

| Coil ID | 450-520mm | |

| Coil OD | Max 15000mm | |

| Coil Weight | 1.0-2.0T | |

| Mill Installed Capacity | 65Kw | |

| Line Area | 50m(Length)*4m(Width) | |