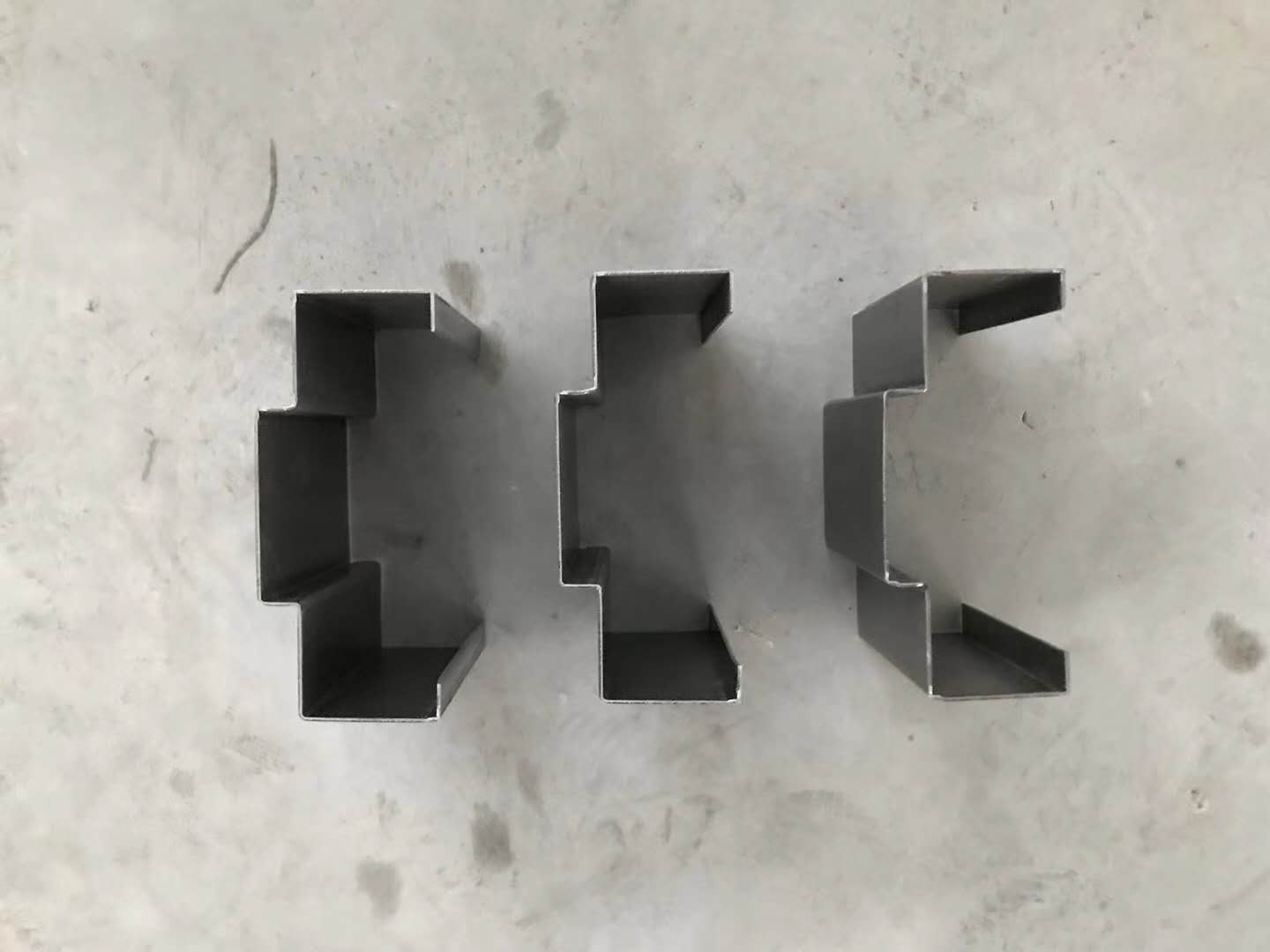

Production Profile:

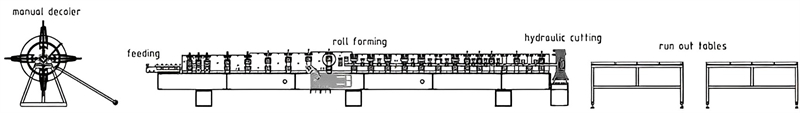

Production Line:

Production Parameters:

| Door Frame Roll Forming Machine | ||

Machinable Material | A) Galvanized Coil | Thickness(MM): 0.7-1.8 According To Your Requirement |

| B) PPGI, PPGL | ||

| Yield Strength | 250 – 350 Mpa / 350-550Mpa | |

| Tensil Stress | 350 Mpa-550 Mpa | |

| Coil Width | As Per The Detailed Profile | |

| Forming Speed | 10-15 m/min | * Or According To Your Requirement |

| Forming Station | 15-18 Stations | * According To Your Profile Drawings |

| Decoiler | Manual Decoiler | * Hydraulic Decoiler (Optional) |

| Driving System | Gear | * Chain(Optional) |

| Machine Structure | Individual Station | * Steel Plates Welded (Optional) |

| Rollers’ Material | 45# | |

| Cutting System | Hydraulic Post Cut | * Hydraulic Servo Tracking Cutter (Optional) |

| Output Way | Roller Table | |

| Frequency Changer Brand | Delta | * Siemens (Optional) |

| Power Supply | 380V 50Hz | * Or According To Your Requirement |

| Machine Color | Industrial Blue | * Or According To Your Requirement |

Production Details: